KUKA KR240 R2500

Industrial Robot KUKA KR240 R2500 PRIME compact and robust design that provides safety and durability and at the same time is lightweight. It is characterized by maintaining the harmony between the load capacity and the range of reach of the robotic arm. Ideal for spot welding processes with optimal cycle times and acceleration, greater precision, minimum maintenance, high performance in the space for assembly and energy efficiency.

KR C4 - Newest Kuka controller

More powerful, safer, more flexible, and above all more intelligent. The revolutionary concept of the KR C4 provides a firm foundation for the automation of tomorrow. It reduces costs in automation for integration, maintenance and servicing. The long-term efficiency and flexibility of the systems are increased at the same time. For this reason, KUKA has developed a new ground-breaking, clearly-structured system architecture that concentrates on open and powerful data standards. In this architecture, all integrated controllers – from SafetyControl, RobotControl, and MotionControl to LogicControl and ProcessControl – have a joint database and infrastructure which they use and share intelligently.

Main specifications

- Maximum Load of Robot: 240 Kg

- Number of axis: 6

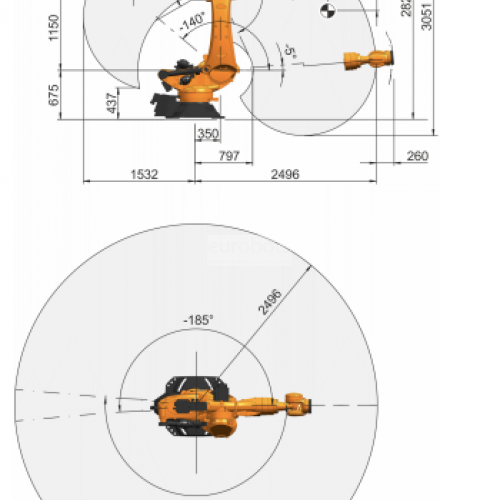

- Maximum reach: 2496 mm

- Repeatability: ±0.06 mm

- Controller: KRC4

Axis data Motion range

- A1 ±185 °

- A2 -140 ° / -5 °

- A3 -120 ° / 155 °

- A4 ±350 °

- A5 ±122.5 °

- A6 ±350 °

Speed with rated payload

- A1 105 °/s

- A2 107 °/s

- A3 114 °/s

- A4 136 °/s

- A5 129 °/s

- A6 206 °/s

Applications

Arc welding , Spotwelding , Press tending , Loading and unloading of parts , Machining , Handling of parts , Measurement , Assembly of parts , Laser cutting , Laser welding Nd-Yag , Glueing - Adhesive bonding , Advanced Manufacturing , Education

Pictures

Videos

Diagrams

English

English

Spain

Spain

Germany

Germany

France

France

Russia

Russia

China

China

Argentina

Argentina

Portugal

Portugal

Colombia

Colombia

Italy

Italy

Brazil

Brazil

Japan

Japan

Mexico

Mexico

Turkey

Turkey

Ukraine

Ukraine

Peru

Peru

Sth. Africa

Sth. Africa