The KR 20 R3100 industrial robot features a streamlined design ideal for gluing and sealing applications. It offers a 20 kg payload and a 3,100 mm reach, making it suitable for wide working areas while maintaining a compact footprint.

It is a standard model, designed for common industrial environments and not suitable for painting processes or potentially explosive atmospheres.

Thanks to its aerodynamic shape, it can operate efficiently in tight workcells.

With its extended reach, it supports a wide range of industrial applications.

It is floor-mounted, features IP65 protection, and uses the KUKA smartPAD teach pendant.

The KR IONTEC series is engineered to deliver superior performance and maximize the working envelope, making it ideal for medium payload tasks. It ensures optimal speed and efficiency, with installation options on the floor, wall, or at an inclined angle.

Its compact design, waterproof wrist, and protected motors make it suitable for many applications, including environments with extreme temperatures (from 0°C to 55°C), thanks to the Foundry option.

The KR IONTEC stands out for its high efficiency, versatility, and cost-effectiveness, representing a strategic investment for the evolution of your production.

Adaptive performance: KR IONTEC offers digital motion modes that allow the robot’s performance to be tuned to different processes, prioritizing either precision or speed as needed.

Reduced maintenance: Maintenance requirements are minimal, with oil changes needed only every 20,000 operating hours. The in-line wrist design eliminates belts.

Efficient cell planning: Efficient use of the work envelope, a reduced footprint, and its streamlined profile allow for compact cell layouts and minimized space requirements.

Cost-effective: The robot requires 50% fewer spare parts than its predecessor, reducing inventory costs.

Adjustable payload: The payload capacity of the KR IONTEC can be modified even after installation, ensuring maximum production flexibility.

Easy commissioning: Optimized technical tools and familiar KUKA technology simplify commissioning and require only minimal training.

Efficient energy routing: The A1 hollow shaft, with a 119 mm diameter, ensures efficient energy supply with minimal bulk.

ESD protection: The robot is equipped with standard ESD protection for safe handling of sensitive electronic components.

High availability: KR IONTEC boasts 99.999% technical availability and a 400,000-hour mean time between failures, ensuring maximum uptime.

| Controlador |

KR C5 KR C4 |

|---|---|

| Número de ejes | 6 |

| Carga útil nominal | 20 kilos |

| Variante | - |

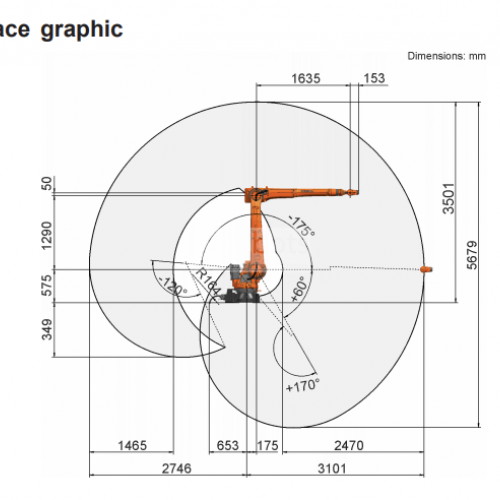

| Alcanzar | 3.101 mm |

| Pose repetibilidad | 0,05 mm |

| Peso | 549 kg |

| Posición de instalación | Piso, techo, pared, ángulo. |

rango de movimiento

A1 ±185°

A2 -175°/60°

A3 -120°/170°

A4 ±350°

A5 ±130°

A6 ±350°

Velocidad con carga útil nominal

A1 180 °/s

A2 165 °/s

A3 160 °/s

A4 360 °/s

A5 360 °/s

A6 630 °/s

Applications

Arc welding , Palletising , Loading and unloading of parts , Machining , Handling of parts , Measurement , Laser cutting , Laser welding Nd-Yag , Glueing - Adhesive bonding , Plasma cutting

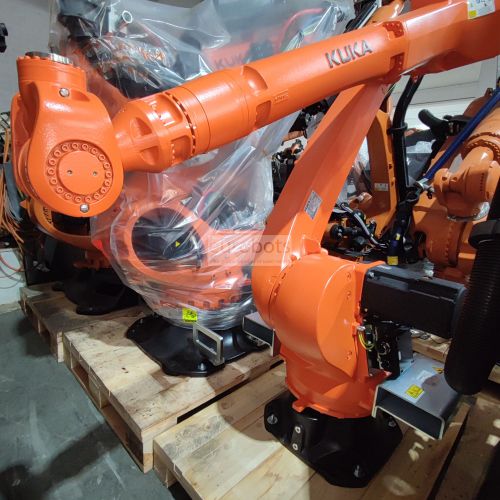

Pictures

Videos

Diagrams