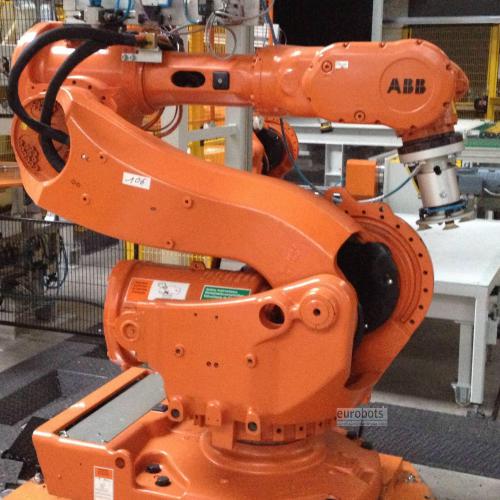

Year 2007. Two 6 axis high payload robots controlled by one single cabinet, fully synchronized allowing complex operations to be performed like handling parts on to the other "on the fly". The 6600 is an evolution of the famous IRB6400. Higher speed and a fully new shape allowing a wider working envelope in axis 2 and 3. Single spring counterbalance system following the Kuka and Fanuc philosophy (Kuka series 2000 and Fanuc R2000). The IRB 6600 comes with a built-in Service Information System, allowing for it to easier plan service and maintenance.

Equipped with the latest IRC5 controller

IRC5 is ABB’s fifth generation robot controller. Its motion control technology, TrueMove & QuickMove, is key to the robot’s performance in terms of accuracy, speed, cycle-time, programmability and synchronization with external devices.

Based on advanced dynamic modeling, the IRC5 optimizes the performance of the robot for the physically shortest possible cycle time (QuickMove) and precise path accuracy (TrueMove). Together with a speed-independent path, predictable and high- performance behavior is delivered automatically, with no tuning required by the programmer.

RAPID programming language

The perfect combination of simplicity, flexibility and powerful- ness. RAPID is a truly unlimited language with hosts of advanced features and powerful support for many process applications.

Communication

The IRC5 supports the state-of-the-art field busses for I/O and is a well-behaved node in any plant network. Sensor interfaces, remote disk access and socket messaging are examples of the many powerful networking features.

Robot Info

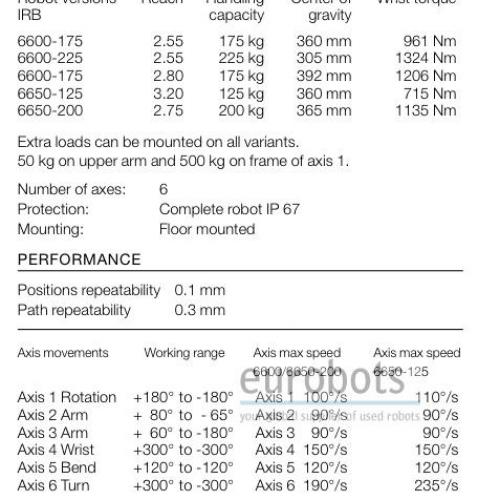

- Maximum Load of Robot: 175 Kg

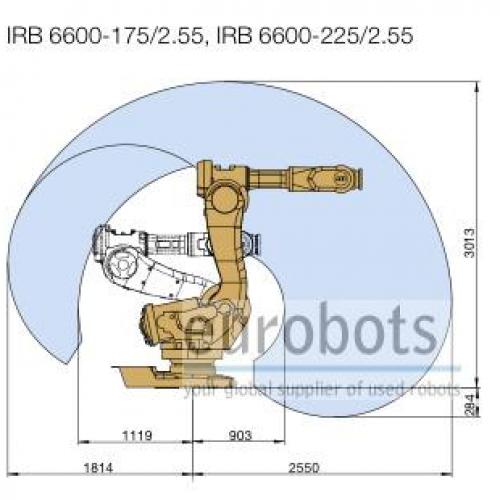

- Maximum Reach: 2550 mm

- Repeatability: 0.1 mm

- Controller: IRC5 M2004 - 1 x controller for 2 x robot arms

Robot Motion Speed

- Axis 1: 100º/s

- Axis 2: 90º/s

- Axis 3: 90º/s

- Axis 4: 150º/s

- Axis 5: 120º/s

- Axis 6: 190º/s

Robot Applications

- Spot welding

- Press tending

- Material handling

- Machine tending

- Palletizing

- Assembly

उपयोग

Pembuatan palet , Lukisan , Memuat dan membongkar suku cadang , Mesin , Penanganan suku cadang , Perakitan bagian , Laser welding Nd-Yag , Pemotongan plasma

चित्र

रेखाचित्र