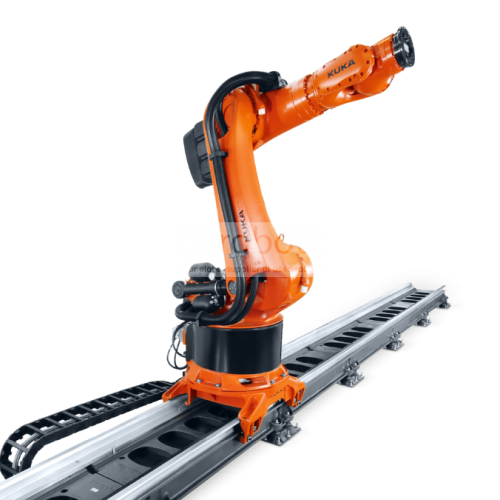

KUKA KL4000 Linear track

Built for the toughest applications.

The KL 4000 enables robots to move massive loads with precision and reliability along the production line. Designed for continuous industrial operation, it combines exceptional load capacity with high positional accuracy, making it a key enabler for flexible, high-throughput automation in heavy industry.

The system is available in a high-speed (S) variant, optimized for applications requiring rapid positioning despite extreme payloads.

Key Benefits

Extreme load capacity

Supports payloads up to 4,000 kg, enabling the handling of large tools, fixtures, and workpieces in heavy-duty industrial environments.

High positional accuracy

Up to four robots can be operated on a single KL 4000 axis. Multiple programmable positions ensure precise adaptation to complex production lines and large workspaces.

Extended reach for large installations

With travel lengths exceeding 30 meters, the KL 4000 significantly multiplies the robot’s effective working range, ideal for linking multiple stations or long transfer lines.

Flexible installation

Available in floor- and ceiling-mounted configurations to suit large-scale automation concepts.

Industrial-grade performance

Engineered for high dynamic loads and continuous operation, the KL 4000 delivers reliable motion, long service life, and stable performance even under extreme conditions.

Productivity optimization

Additional driven or non-driven carriages enable the transport of tools, fixtures, or workpieces along the axis, reducing handling time and increasing overall throughput.

The KL 4000 is KUKA’s heavy-duty linear unit designed for very high payloads of up to 4,000 kg. It is specifically engineered for large robot systems such as the KR QUANTEC, KR FORTEC, KR 300 PA, and KR 470 PA series, making it ideal for demanding applications including heavy material handling, large part machining, palletizing, and automotive body construction.

The KL 4000 can be installed in floor or ceiling-mounted configurations, providing flexibility for large-scale production layouts. By adding a powerful linear axis, the robot’s working envelope is expanded across long distances, allowing a single robot to service multiple stations, fixtures, or process steps with maximum efficiency.

As with all KUKA linear units, the KL 4000 is integrated as an external axis, meaning no additional controller is required, simplifying system architecture and reducing integration effort.

उपयोग

Pengelasan busur , Pengelasan spot , Tekan merawat , Pembuatan palet , Memuat dan membongkar suku cadang , Mesin , Penanganan suku cadang , Poles , Pengukuran , Perakitan bagian , Laser cutting , Laser welding Nd-Yag , Lem - Ikatan perekat , Stud welding , Pemotongan plasma , Advanced Manufacturing , Education , sel penggilingan

चित्र

रेखाचित्र

English

English

Spain

Spain

Germany

Germany

France

France

Russia

Russia

China

China

Argentina

Argentina

Portugal

Portugal

Colombia

Colombia

Italy

Italy

Brazil

Brazil

Japan

Japan

Mexico

Mexico

Turkey

Turkey

Ukraine

Ukraine

Peru

Peru

Sth. Africa

Sth. Africa