KUKA KR210-2

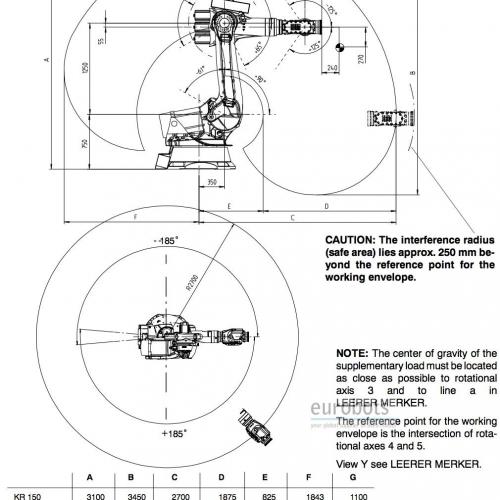

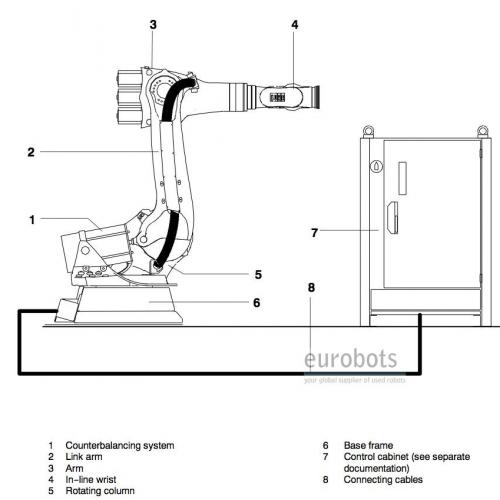

Heavy payload 6 axis industrial robot available in three versions attending to the arm reach / payload: KR 210-2 (2700 mm / 210 kg) , KR 210L180-2 (2900 mmm 180 kg) , KR 210L150-2 (3100 mm / 150 kg).

Suitable for machining, spotwelding, machining, handling and palletizing applications.

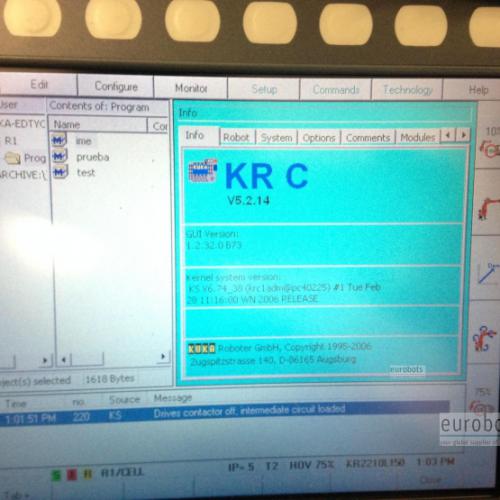

Equipped with the KRC2 controller available in two versions attending to the software version: 4.1.7 running on Win95 or 5.2.9 on WinXP platform.

The KR C2 robot controller makes programming easier with its Microsoft Windows interface. It is expandable, can be integrated into networks via a bus, and contains ready-made software packages.

KR C2 features

* Open, network-capable PC technology

* 2 free slots for external axes

* DeviceNet and Ethernet slots for common bus systems (e.g. INTERBUS, PROFIBUS, DeviceNet) provided as standard

* Motion profile function for optimal interaction between the individual robot motors and their velocity

* Floppy disk and CD-ROM drives for data backup

* Facilities such as remote diagnosis via the Internet

* Simple operation and programming via KUKA Control Panel (KCP) with Windows user interface

* Compact control cabinet

* Ergonomic KUKA Control Panel (KCP)

Robot Info

Maximum Load of Robot: 210/180/150 Kg

Maximum Reach: 2700/2900/3100 mm

Repeatability: 0.15

Controller: KR C2

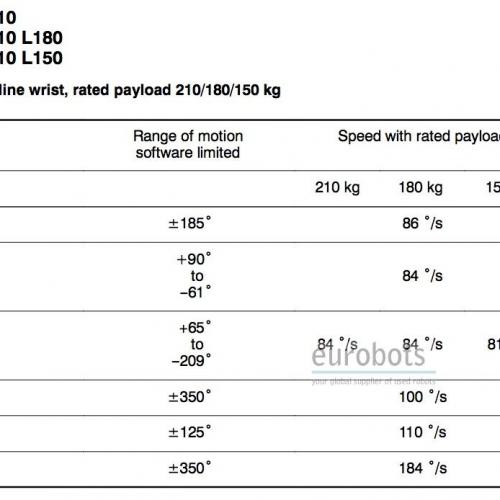

Axis Speed in º/s for the models: KR 210-2 / KR 210 L180-2 / KR 210 L150-2

Axis 1: 86º/s (all 3 models)

Axis 2: 84º/s (all 3 models)

Axis 3: 84º/s 84º/s 81º/s

Axis 4: 100º/s (all 3 models)

Axis 5: 110º/s (all 3 models)

Axis 6: 184º/s (all 3 models)

Range of motion (Axis 1 to 6)

Axis 1: +- 185º

Axis 2: +90 to -61º

Axis 3: +65º to -209º

Axis 4: +-350º

Axis 5: +-125º

Axis 6: +-350º

उपयोग

Pengelasan spot , Tekan merawat , Pembuatan palet , Memuat dan membongkar suku cadang , Mesin , Penanganan suku cadang , Lem - Ikatan perekat , Stud welding , Pemotongan plasma

चित्र

वीडियो

रेखाचित्र

English

English

Spain

Spain

Germany

Germany

France

France

Russia

Russia

China

China

Argentina

Argentina

Portugal

Portugal

Colombia

Colombia

Italy

Italy

Brazil

Brazil

Japan

Japan

Mexico

Mexico

Turkey

Turkey

Ukraine

Ukraine

Peru

Peru

Sth. Africa

Sth. Africa