Motoman HP6

Year 2005. Equipped with the latest NX100 controller.

Slim and powerful 6 kg payload high-speed robot ideal for a wide variety of applications including for arc welding, packaging, and handling.

The HP6 offers high flexibility - it has full 6-axis capability; and can be floor, wall or ceiling mounted; or supplied as a twin system (two robots; one controller), a triple system (three robots; one controller) or even a quad system (four robots; one controller).

The HP6 features the widest working envelope in its class (1378mm reach) and has high reliability and high repeatability.

NX100 - the Next Generation of Robot Controller

Faster, feature-packed, highly reliable and easier to use - Motoman's new NX100 robot control system has arrived. NX100 is the PC-based high performance robot controller.

The NX100 controller features a Windows® CE programming pendant with full colour LCD touch screen display. It offers high speed processing, unmatched memory (60,000 steps, 10,000 instructions), built-in ethernet and a robust PC-architecture.

The NX100 easily handles multiple tasks and can control up to four robots plus external axes (max 36 axes) and I/O devices. Advanced Robot Motion control (ARM) provides high performance path accuracy and motion control.

The control system's PC architecture offers unlimited communication with other systems via a wide range of communication protocols. The improved integrated PLC will in many cases eliminate the need for a separate PLC, saving costs at the system level.

Multiple robot control

Real time synchronisation of up to four robots and external axes (max.36 axes)

- Jigless welding possible

- Enables high density robot layouts

- Reduced cycle times

- User friendly touch screen pendant

With Windows CE operating system and a full colour LCD touch-screen display

- Complete access tto all operations from programming to maintenance

- Reduced programming time

- Possibility to create your own user menus

- Eliminates the need for separate operator's panel

Advanced robot motion (ARM) control

Dynamic calculation of robot axis torque and loan (an original Motoman development)

- High performance path accuracy

- Optimised robot motion & speed

- Short pitch function

- Collision detection

Communication features

Built-in Ethernet;Web, FTP and OPC server options

Fieldbus support of the 15 most common brands on the market

- Easy to connect to existing networks

- Remote monitoring and diagnostics of robot systems

Robot Info:

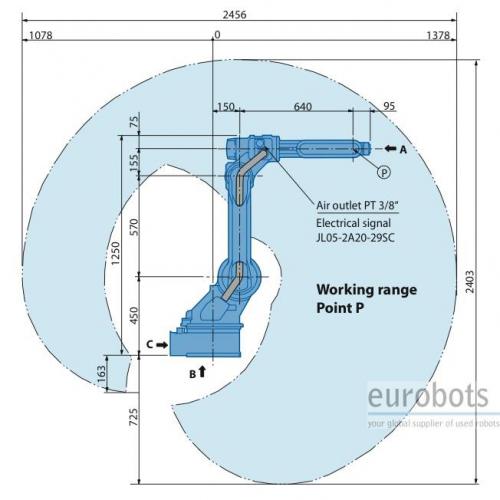

- Maximum Load of Robot: 6Kg.

- Maximum Reach: 1390 mm.

- Repeatability: 0,08 mm.

- Controller: NX100

Robot Motion Speed:

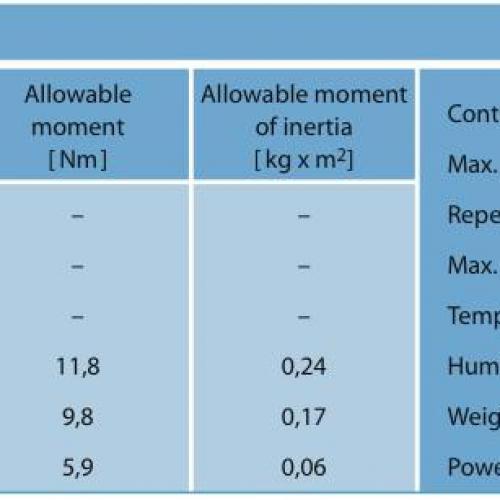

- Axe 1: 150º/seg

- Axe 2: 160º/seg

- Axe 3: 170º/seg

- Axe 4: 340º/seg

- Axe 5: 340º/seg

- Axe 6: 520º/seg

Robot Applications:

- Arc welding

- Machining

- Machine tending

- Polishing, grinding and deburring

- Coating and bonding

- Handling

- Measuring and testing

- Assembly

- Palletizing and order picking

- Cutting

उपयोग

Pengelasan busur , Tekan merawat , Pembuatan palet , Lukisan , Memuat dan membongkar suku cadang , Penanganan suku cadang , Poles , Perakitan bagian , Lem - Ikatan perekat

चित्र

वीडियो

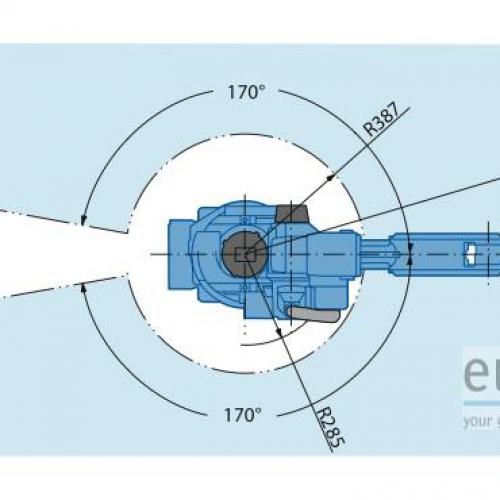

रेखाचित्र

English

English

Spain

Spain

Germany

Germany

France

France

Russia

Russia

China

China

Argentina

Argentina

Portugal

Portugal

Colombia

Colombia

Italy

Italy

Brazil

Brazil

Japan

Japan

Mexico

Mexico

Turkey

Turkey

Ukraine

Ukraine

Peru

Peru

Sth. Africa

Sth. Africa